DU-SRM

The DU-SRM technology platform can be used in a range of applications:

Electrical cars/hybrid electrical vehicles

The development of the Double U-core Switched Reluctance motor is based on the further development of the ETFM technology to fit the requirements for electric and hybrid vehicles. For electric vehicles, a DU-SRM with 3 phases and inner rotor is most frequently recommended. The size of the current DU-SRM is optimized as a near-wheel motor, operating through a integrated gear box, with either 2 or 4 motors per vehicle:- Peak power: 35 kW

- Continuous power: 17,5 kW

- Peak torque: 106 Nm.

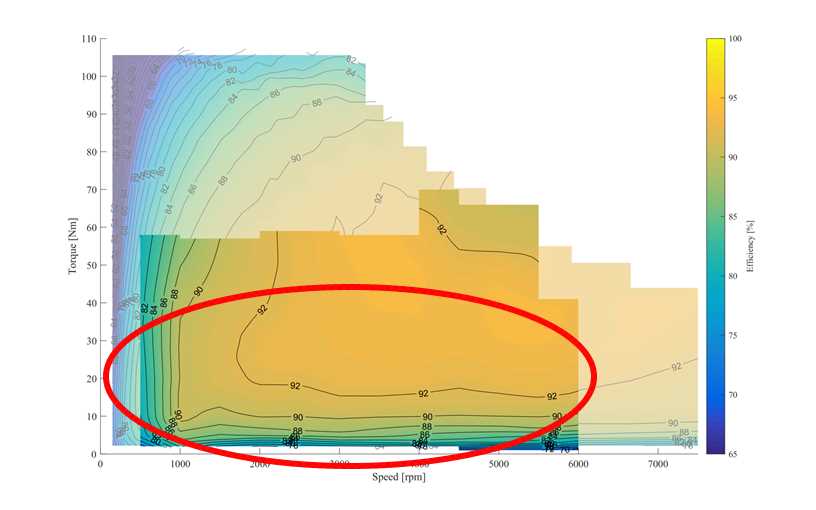

High efficiency over large speed range

Over 90% of the driving time the motor-torque in electrical vehicles is less than 30% of the maximal torque (red ring on the picture).The DU-SRM has very low losses at low torque and high speed. In that area, the traditional Permanent Magnet motors have a high loss, due to magnetic iron losses.

In general, the DU-SRM has a very high efficiency and torque density compared to other non-magnetic motors.

The zero loss (except losses from ball bearings) when free-wheeling is even more important in Hybrid vehicles where the electric motor is turned off in a large part of the driving time when the conventional fuel motor is driving the car.

Fail safe operation

The Double U-core SR motor is highly stable and faults tolerant by nature. The simple construction only consist of standard copper wire and iron laminate which makes it possible to work in the harsh outdoor environment such as electrical transport. If a fault should occur in a coil, the structure with electric, magnetic and mechanical separated phases and no permanent magnets makes it possible to handle the fault and bring the vehicle safe to the nearest stop.Turbines (waste energy)

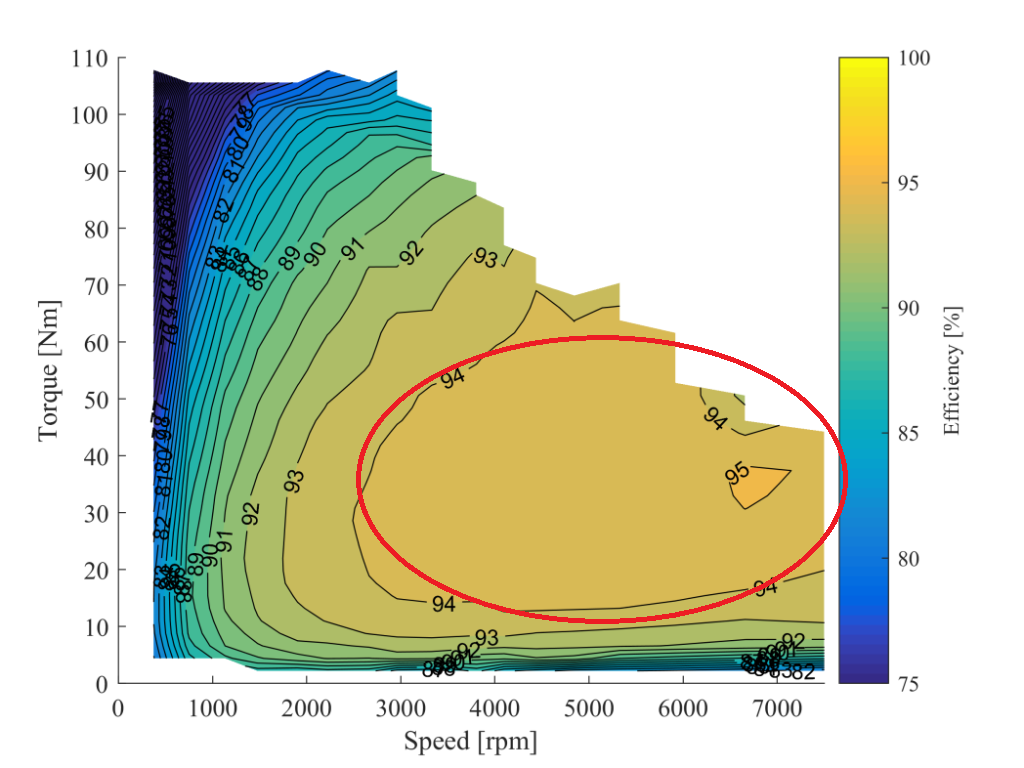

A one-phase outer rotor DU-SR motor is optimum for turbine applications from 10-500 kW. An example with a 100 kW DU-SRM has been designed for a high-speed (7000 RPM) turbine for a low-density medium.The DU-SR motor has an efficiency above 94% over a large area and keeps the high efficiency even with a partial load (red ring on the picture).

The simple modular construction makes it possible to integrate the motor and turbine as one dedicated and efficient unit. The use of standard materials, like copper and iron laminate, makes the DU-SRM resistant to the harsh environment in a turbine application.